Introduction

In the dynamic world of manufacturing, fiber laser cutting machine stands out as a pivotal innovation, enhancing precision and efficiency. As Winnipeg emerges as a significant hub for manufacturing, identifying the best fiber laser cutting machine manufacturers is crucial. Among them, SLTL (Sahajanand Laser Technology Ltd.) has distinguished itself as a leader. This article explores the fiber laser cutting landscape in Winnipeg, spotlighting why SLTL is the preferred choice.

Overview of Fiber Laser Cutting Technology

- Definition and Importance

Fiber laser cutting technology uses high-powered laser beams to cut through materials with remarkable precision. This method is renowned for its speed, accuracy, and ability to handle various materials, including metals, plastics, and composites. Its importance lies in its contribution to improved production quality and efficiency, making it a staple in modern manufacturing.

- Applications in Various Industries

Fiber laser cutting is utilized across diverse industries. In automotive manufacturing, it ensures precision in creating parts. The aerospace industry relies on it for cutting complex components, while the electronics sector uses it for delicate, intricate patterns. Other industries like medical device manufacturing and jewelry design also benefit from its capabilities.

Importance of Choosing the Right Manufacturer

- Impact on Productivity

Selecting the right fiber laser cutting machine manufacturer significantly impacts productivity. High-quality machines reduce downtime, minimize errors, and enhance production speed, contributing to overall efficiency.

- Cost Efficiency and ROI

Investing in the right equipment can yield substantial cost savings in the long run. Efficient machines consume less energy, require fewer repairs, and have longer lifespans. The return on investment (ROI) from high-quality fiber laser cutting machines justifies the initial expenditure, as they boost output and reduce operational costs.

The Fiber Laser Cutting Machine Market in Winnipeg

- Overview of the Manufacturing Landscape in Winnipeg

Winnipeg’s manufacturing sector is diverse, encompassing industries like aerospace, transportation, and agriculture. The demand for precision cutting tools is high, driving the growth of the fiber laser cutting machine market in the region.

- Key Industries and Their Needs

Industries in Winnipeg require cutting-edge technology to maintain competitiveness. Aerospace manufacturers need precise cutting for aircraft components, while the transportation sector relies on high-quality cuts for vehicle parts. Agricultural equipment manufacturers also demand robust and reliable machines.

- Market Trends and Growth

The fiber laser cutting machine market in Winnipeg is on an upward trajectory. Advances in technology, increasing automation, and the need for precision drive this growth. Manufacturers continually seek innovative solutions to enhance production capabilities.

Top Fiber Laser Cutting Machine Manufacturers in Winnipeg

- Criteria for Selection

Choosing the top manufacturers involves evaluating factors like technology, reliability, customer support, and market reputation. Manufacturers that excel in these areas stand out as leaders.

- Market Leaders Overview

Several manufacturers have made their mark in Winnipeg’s fiber laser cutting machine market. Among them, SLTL is recognized for its innovation, quality, and customer-centric approach.

Spotlight on SLTL (Sahajanand Laser Technology Ltd.)

- Company Background and History

SLTL, founded in 1989, has grown into a global leader in laser technology. With a strong presence in over 30 countries, SLTL is synonymous with innovation and quality.

- Founding and Evolution

Starting as a small enterprise, SLTL evolved by consistently pushing the boundaries of laser technology. Today, it is a trusted name in fiber laser cutting, known for its cutting-edge solutions.

- Global Presence and Influence

SLTL’s global footprint underscores its reliability and technological prowess. Its machines are used worldwide, reinforcing its status as a leading manufacturer.

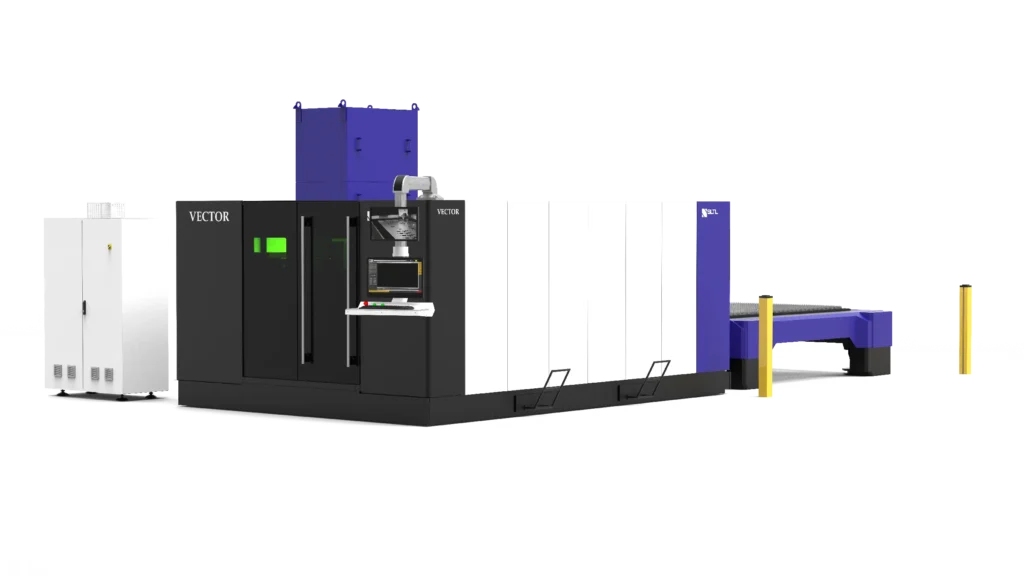

SLTL’s Fiber Laser Cutting Machines: An Overview

- Product Lineup

SLTL offers a comprehensive range of fiber laser cutting machines tailored to various industrial needs. Their lineup includes models for different scales of production, ensuring there is a solution for every requirement.

- Key Features and Innovations

SLTL machines are equipped with advanced features like high-speed cutting, automated loading and unloading systems, and intuitive control interfaces. These innovations enhance efficiency and user experience.

Detailed Analysis of SLTL Fiber Laser Cutting Machines

Technological Innovations by SLTL

- Advanced Laser Technology

SLTL’s fiber lasers use state-of-the-art technology to deliver unmatched precision and speed. Their advanced beam quality ensures clean cuts and minimal material wastage.

- Software and Automation

The integration of sophisticated software and automation in SLTL machines simplifies operations. Automated processes reduce human error and increase productivity.

Performance and Efficiency

- Cutting Speed and Precision

SLTL machines are known for their high cutting speeds and precision. This combination ensures faster production cycles and superior product quality.

- Energy Consumption and Cost Savings

Energy efficiency is a hallmark of SLTL fiber laser cutting machines. They consume less power, translating to significant cost savings over time.

Quality and Reliability

- Material Handling and Versatility

SLTL machines handle a wide range of materials, from thin sheets to thick plates, with ease. This versatility makes them ideal for various industrial applications.

- Durability and Maintenance

Built to last, SLTL machines require minimal maintenance. Their robust construction and high-quality components ensure long-term reliability.

Benefits of Choosing SLTL for Fiber Laser Cutting

Enhanced Productivity

- Time-Saving Features

SLTL machines incorporate features that streamline production processes, reducing cycle times and increasing output.

- Reduction in Downtime

Reliability and ease of maintenance minimize downtime, ensuring continuous operation and higher productivity.

Cost-Effectiveness

- Long-Term Savings

Investing in SLTL machines leads to long-term cost savings due to their efficiency, durability, and low operational costs.

- ROI Analysis

The initial investment in SLTL fiber laser cutting machines is justified by the significant ROI achieved through improved production and reduced costs.

Support and Service

- Training and Installation Services

SLTL provides comprehensive training and installation services, ensuring users can maximize the potential of their machines from day one.

- After-Sales Support and Maintenance

Ongoing support and maintenance services from SLTL ensure that machines operate at peak efficiency throughout their lifespan.

Future Trends in Fiber Laser Cutting Technology

- Innovations on the Horizon

Emerging technologies promise further advancements in fiber laser cutting. Innovations like AI integration and advanced automation are set to revolutionize the industry.

- Emerging Technologies

The incorporation of AI and machine learning in fiber laser cutting will enhance precision, efficiency, and adaptability, making machines smarter and more autonomous.

- Predictions for the Next Decade

The next decade will likely see significant advancements in fiber laser cutting technology, driven by continuous R&D and market demands.

Conclusion

SLTL stands out in Winnipeg’s fiber laser cutting machine market due to its innovative technology, reliability, and customer-focused approach. Choosing the right manufacturer is crucial for enhancing productivity, achieving cost efficiency, and ensuring long-term success. From advanced technology to exceptional customer support, SLTL offers unmatched benefits, making it the top choice for fiber laser cutting machines in Winnipeg. By focusing on quality, innovation, and customer satisfaction, SLTL continues to lead the market.

Leave a Reply